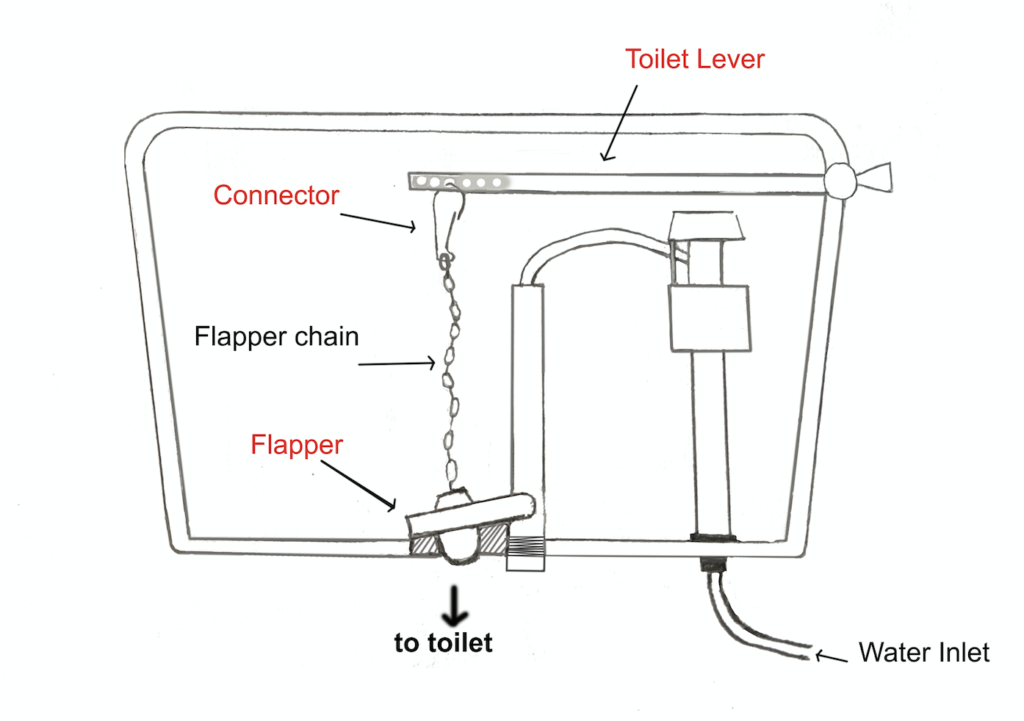

When you pull the handle of a toilet, many things happen inside the toilet tank. As the handle is pulled down, the lever arm goes up, which pulls on a chain connected to a flapper. The flapper is the rubber barrier between the toilet bowl and the tank. So when the flapper is pulled up, water in the tank rushes into the toilet bowl to produce a flush. The flapper returns to a closed position when the flush is complete. Water starts to fill up the tank to start the cycle over again. As the tank fills up, the water supply is shut off by a buoy mechanism.

Common Issues

There are 3 main types of toilets based on how flushing is initiated. The first type is via a lever system that triggers a chain reaction when you press a handle down. The second type is equipped with a flush button. There are often two buttons, one for a major flush and another for a small flush to save water. Finally, there are toilets that are triggered by infrared, and they flush after the sensor detects a user has left the toilet. Below, we will mainly focus on the lever-mechanism, which the majority of households in the USA have.

FLAPPER CHAIN

Sometimes, the flapper chain is caught under the flapper which results in the flapper not being able to close correctly. This is also a random issue like what is caused by the jammed connector but it is usually less common than the latter.

Solution: Adjust the length of the chain so that it is physically impossible to have the chain stuck under the flapper.

FLAPPER WEAR

Through normal wear and tear, the flapper is unable to seal water inside the tank, resulting in a slow and continuous flow of water. If this happens, the water will continuously flow at a relatively slow rate. This issue is easy to spot.

Solution: There isn’t a whole lot you can do, so the only option is to buy a new flapper.

JAMMED CLIP

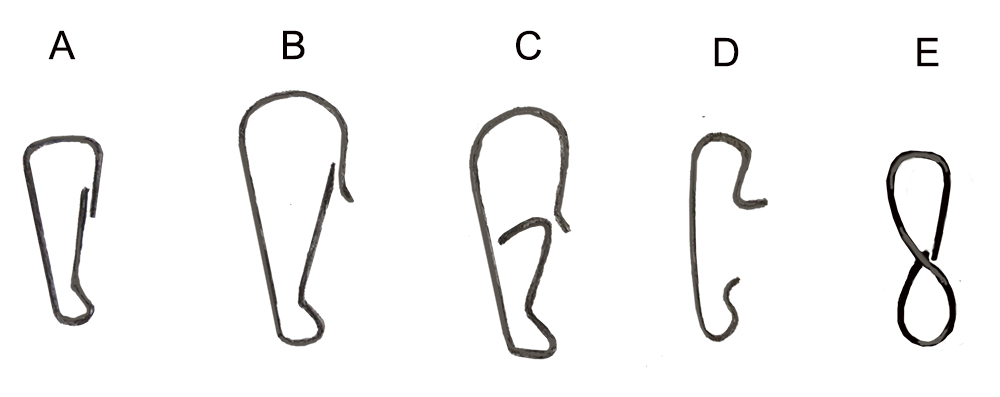

Sometimes the connector between the lever arm and the chain will become stuck at an angle. The stuck position can often raise the flapper so that it can’t close properly. As a result, water will keep moving at a full flow rate from the tank to the toilet bowl. This will go on until you come back to the toilet and see water running. The unpredictable nature of this issue makes it very difficult to spot. Many households simply stop the flow by pressing toilet flush handle again and move on without realizing how much water they could lose due to this issue. Below is an image showing the clip in a stuck position, with water being wasted.

The solution to this is more complicated, so read on to find out what to do.

How To Fix a Stuck Connector

If the connector sometimes becomes stuck at an angle you may have a very large problem at your hands. This is because you never know when the jamming may occur. Therefore, it is very hard to eliminate this problem because of the unpredictable nature. We invented a very simple solution for this.

Custom Connector

We wanted to create a solution for anyone experiencing these problems so we created a custom connector. The item is a durable, rust resistant ring with a screw-connector, which acts as a substitute for a traditional connector. The ring is circular in design and unable to jam. Therefore, by using this connector, the flapper will never be stuck open. The ring is also easy to use and can be installed without any tools. If you are interested, you can request a connector for free.